Search This Supplers Products:Infrared BurnerInfrared HeaterInfrared gas BurnerGas heaterBBQ Grill BurnerOven Heater

- Home

- About us

- Products

- Infrared Burners

- Industrial infrared burners

- BBQ infrared burners

- Metal net burners

- Powder coating oven burners

- Baking oven burners

- Industry drying oven burners

- Poultry farm heater&brooders

- Infrared indoor heaters&stoves

- Ungrouped

- Industrial Infrared Heater

- Barbeque Grill Burner

- Solenoid Valves

- Burner Spare Parts

- Igniter&accessoreis

- Faqs

- News

- Certificate

- Contact us

Industrial infraed gas heater

- group name

- Infrared Burners

- Min Order

- 200 piece

- brand name

- HAODONG

- model

- HD162

- update time

- Fri, 15 Mar 2013 15:35:23 GMT

Paramtents

Gas resource LPG/NG

Life Above 11000hr

Advantage Energy saving

Packging & Delivery

-

Min Order200 piece

Briefing

2.High radiation efficiency

3.Energy saving

4.Extremely durable

5.Market:Ameri

Detailed

1.Low emissions (NOx,CO)

2.High radiation efficiency

3.Energy saving

4.Extremely durable

5.Market:America,Asia,Euro,Mideast

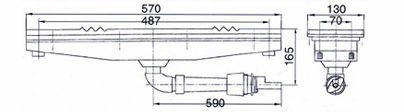

Model | Length (mm) | Width (mm) | Hight(mm) | Weight (kg) | Consumption | Heat Output | Inlet Port (Inch) | ||

NG | LPG | ||||||||

m3/h | kg/h | KW/h | Kcal/h | 3/8 | |||||

HD162 | 570 | 130 | 175 | 8.0 | 0.49 | 0.45 | 6.3 | 5400 | |

Material Descriptions:

Shell: gray cast iron

Upper cover : stamped stainless iron

Burning net: Fe-Cr-Al material

Nozzle: brass

Core components: cordierite honeycomb burner plates with rare-earth catalyst-coated

Working principles of the product:

Infrared catalytic burner uses the porous cordierite honeycomb combustion plate with a special catalyst coated as a core component .

Its catalytic combustion is the best combustion mode ,which means that gas (natural gas, liquefied petroleum gas) and combustion-supporting gas (air) are mixed according to the scientific proportion through burner shell (pre-mixed room) with the precise design and manufacturing . Ignited by the ignition, the gas mixture is burning on surface of catalyst which lies in the holes of porous cordierite honeycomb plate .The vast majority(95%) of the heat generated in the form of infrared radiation penetrate the object directly,put an end to energy loss caused by heating the air to heat the object, the mode of heat convection heating , greatly improve the energy conversion ability so as to further save the energy (save 60% of the operation costs under the same industrial conditions compared to the ordinary heating mode --electric heating ).Gas is almost under complete combustion as a result of catalytic combustio. the flue gas pollution is extremely low (CO <0.02%, NO x <10ppm) ,fully meeting the national environmental standards and there is no need for direct exhaust fan.

The user manual

Table 1:The use of technical parameters

Items

| Technical parameters |

Types |

natural gas (NG),liquefied petroleum gas (LPG)

|

Light-off temperature | ≥350 |

complete combustion temperature | ≤380 |

Heat source temperature

| around 850 |

Baking temperature range | 30---850 |

Wavelength range | 1.9μm--15μm |

Furnance pressure natural | 2000pa(NG)/2800pa(LPG) |

Main purposes:

1. Coating Industry: forging heat coating, liquid, powder coating, pre-heating the water to deal with dry acid.

2. The food industry: drying for processed food such as cookies, egg rolls, snow rice cakes, shredded squid, fish sauce, ham etc;tea processing and baking.

3. Agriculture and animal husbandry: keeping warm for a variety of birds, the livestock shed;grain drying.

4. Food and beverage industry: all kinds of barbecue, fruit and vegetable dehydration.

5. Drying operation in printing and dyeing, paper, wood, carpet and other industries

6. Bake ceramic mold industry, the Health and embryos, the surface drying of glazed ceramic tiles.

7. The heat treatment of metallic materials (300 --- 800 ).

8. Heating ,warming and insulation for commercial buildings and workshop