Search This Supplers Products:Infrared BurnerInfrared HeaterInfrared gas BurnerGas heaterBBQ Grill BurnerOven Heater

- Home

- About us

- Products

- Infrared Burners

- Industrial infrared burners

- BBQ infrared burners

- Metal net burners

- Powder coating oven burners

- Baking oven burners

- Industry drying oven burners

- Poultry farm heater&brooders

- Infrared indoor heaters&stoves

- Ungrouped

- Industrial Infrared Heater

- Barbeque Grill Burner

- Solenoid Valves

- Burner Spare Parts

- Igniter&accessoreis

- Faqs

- News

- Certificate

- Contact us

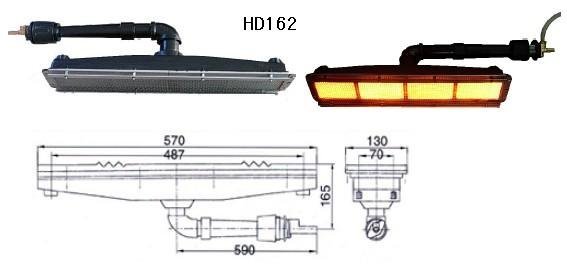

Temperature-controlled infrared ceramic burner HD162

- group name

- Infrared Burners

- Min Order

- 100 piece

- brand name

- HAODONG

- model

- HD162

- update time

- Fri, 15 Mar 2013 15:32:34 GMT

Paramtents

Max-working pressure range LPG 5000pa

CO less than 80ppm

Fuel NG,LPG

CHx less than 50ppm

Burner plate cordierite honeycomb with rare-earth catalyst-coated

Power Source Natural Gas

Packging & Delivery

-

Min Order100 piece

Briefing

2.Engergy transfer rate above 95%

3.Independent use

4.Low cost of equipment.

Detailed

1.Infrared ceramic burner

2.Engergy transfer rate above 95%

3.Independent use

4.Low cost of equipment.

5. Life above 11000hr

Temperature-controlled infrared ceramic burner HD162

Model | Length (mm) | Width (mm) | Hight(mm) | Weight (kg) | Consumption | Heat Output | Inlet Port (Inch) | ||

NG | LPG | ||||||||

m3/h | kg/h | KW/h | Kcal/h | 3/8 | |||||

HD162 | 570 | 130 | 175 | 8.0 | 0.49 | 0.45 | 6.3 | 5400 | |

Technology Features:

This ceramic infrared burner used our Haodong catalytic technology.The burning occurs on the covering catalyst and radiate infrared ray, energy transfer can reach 95%. But the common infrared burner, it radiates by heating the ceramic, transfer rate only 80~85%. So, infrared catalytic ceramic plate will save much energy than other common infrared plate.

Consumption Comparison:

Furnace type | Electronic | Oil furnace | Coal-fired furnace | Infrared heater | Infrared catalytic heater |

| | | | | |

| | |

| | |

Energy consumption | | | | |

|

| | | |

|

|

|

20 minutes |

40minutes |

90 minutes |

6-10 minutes | |

Application:

Infrared catalytic ceramic burner is good choice industrial drying,baking or curing oven,especially in tunnel&converyor oven,saving production&equirpment cost,demand of space is small and easy to control......It martched with auto-igntion,safe controller and keep stable temperature.Now is already widely used industrial drying,especially in metal curing & food baking.......

Food Industry: Rice Biscuit( rice cookies covered with snow-like sugar )assembly line, grilled chicken, biscuit, egg roll, roasting shredded squid oven, oven for roast duck, smokeless oven, griddle, middle eastern oven, hot pot oven, roasting pachyrhizus oven, snack car, soup oven, cooking assembly line, infra-red gas baking pan, deep-fry assembly line, water-removing machine, baking, etc.

Painting Industry: Liquefied or powered painting assembly line, warm-up, preliminary treatment of heating, desiccating wood, galvanization drying assembly line, phosphatization drying assembly line

Fiber industry: Carpet latex dryer, dyeing dryer, printing dryer, textile dryer, industrial clothes dryer, latex gloves drying assembly line

Glass and ceramics industry: Enamel firing dryer, glass oven, heat-setting machine, mould drying, fritting, parching

Paper industry: All kinds of paper dry lines and auxiliary drying heat wall

Farming and animal husbandry: Heating of barton, heating of crops, grain dryer.

Detail Photos:

Application photos:

1. FILM FACE PLYWOOD Preheating glue.

1. FILM FACE PLYWOOD Preheating glue.

2. Color steel curing oven